LTS LOHMANN Therapie-Systeme AG (“LTS”) and Grand River Aseptic Manufacturing (“GRAM”) proudly announce their strategic alliance focused on the sterile fill finish for containers used in LTS’ Sorrel™ wearable injector devices

LTS LOHMANN Therapie-Systeme AG (“LTS”) and Grand River Aseptic Manufacturing (“GRAM”) proudly announce their strategic alliance focused on the sterile fill finish for containers used in LTS’ Sorrel™ wearable injector devices. This collaboration offers pharmaceutical companies a comprehensive solution for both the development and manufacturing of wearable injectors specifically designed for the delivery of biologics. This collaboration ensures an integrated approach from concept to completion, facilitating faster market access and streamlined production processes.

Sorrel™ is a next-generation on-body delivery system for large-volume and/or viscous drug formulations designed for patient convenience and pharmaceutical efficiency. Its patented technology supports multiple drugs and indications for smart, reliable at-home delivery. Intuitive for users, Sorrel™ helps pharmaceutical partners reduce development risks like safety, efficacy, cost, and time-to-market.

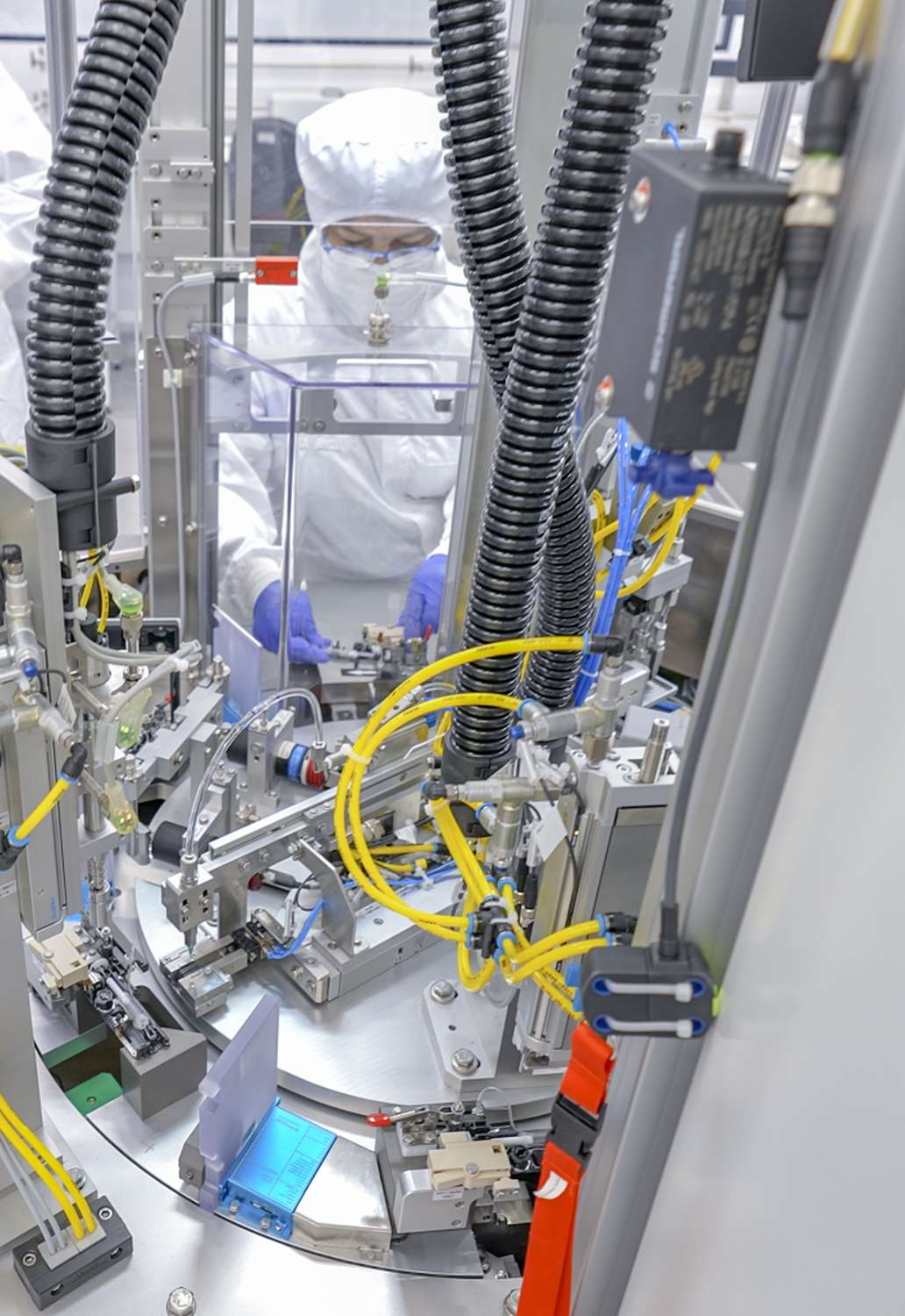

Grand River Aseptic Manufacturing (GRAM) is an aseptic filling and finishing expert, particularly for injectable biologics. Their capabilities span sterile production, regulatory guidance, and product development support with scalable manufacturing solutions tailored to diverse pharmaceutical needs. GRAM is adept at handling the complex requirements of sterile fill finish for specialized containers such as cartridges and wearable injectors, leveraging its extensive expertise to benefit pharmaceutical clients.

Pharmaceutical companies can benefit from a strategic collaboration between LTS and GRAM, offering an end-to-end solution for delivering advanced on-body delivery systems with pre-loaded and pre-filled containers. This collaboration streamlines product development, commercialization, and delivery of Sorrel™ Devices by combining LTS’s innovative device solutions with GRAM’s specialized aseptic manufacturing capabilities.

“We see a very synergistic alliance between LTS and GRAM, creating a mutually beneficial collaboration that particularly supports our customers’ journey from molecule to market,” said Dr. Andrei Yosef, President and General Manager of LTS Device Technologies. “The combination of GRAM’s fill-finish expertise with LTS’s proprietary Sorrel™ drug delivery technology will deliver a streamlined solution that meets the unique needs of our customers.”

“We are excited to embark on this collaboration with LTS, as on-body wearable injectors are crucial for advancing patient care. This collaboration leverages our dedicated efforts, combining GRAM’s specialized aseptic manufacturing capabilities with LTS’s innovative device technology. Together, we are not only advancing the technology but also enhancing patient care by making sophisticated treatments more accessible and easier to use.” — Dave Powell, Vice President of Business Development at Grand River Aseptic Manufacturing (GRAM)

About SorrelTM

The SorrelTM technology allows pre-filled, pre-loaded and pre-assembled wearable drug delivery device that provides an easy-to-use wearable device for at home administration. The SorrelTM platform ranges from 1mL to 50 mL and is primary container agnostic to provide seamless integration into the pharma company product.

About LTS

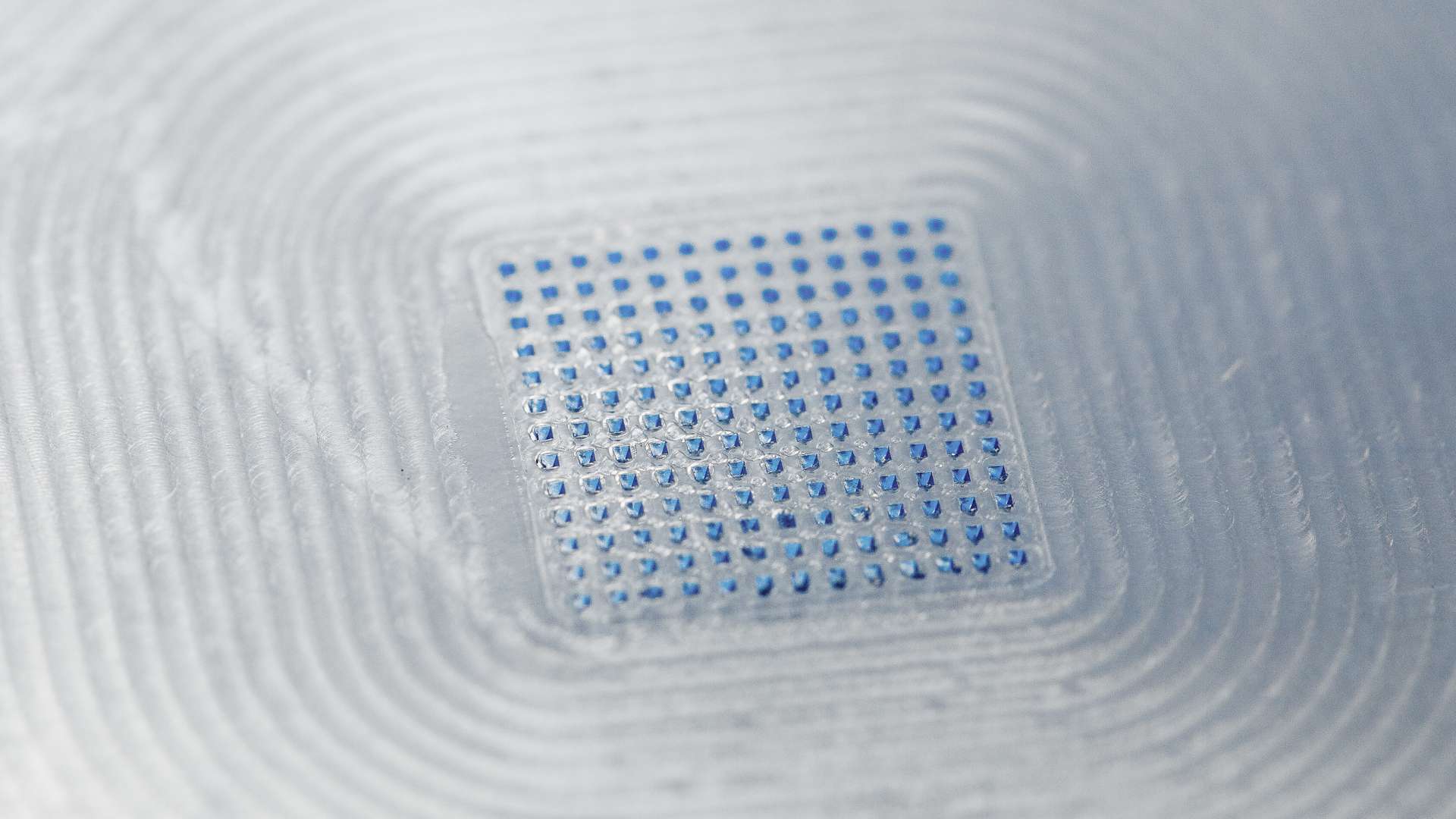

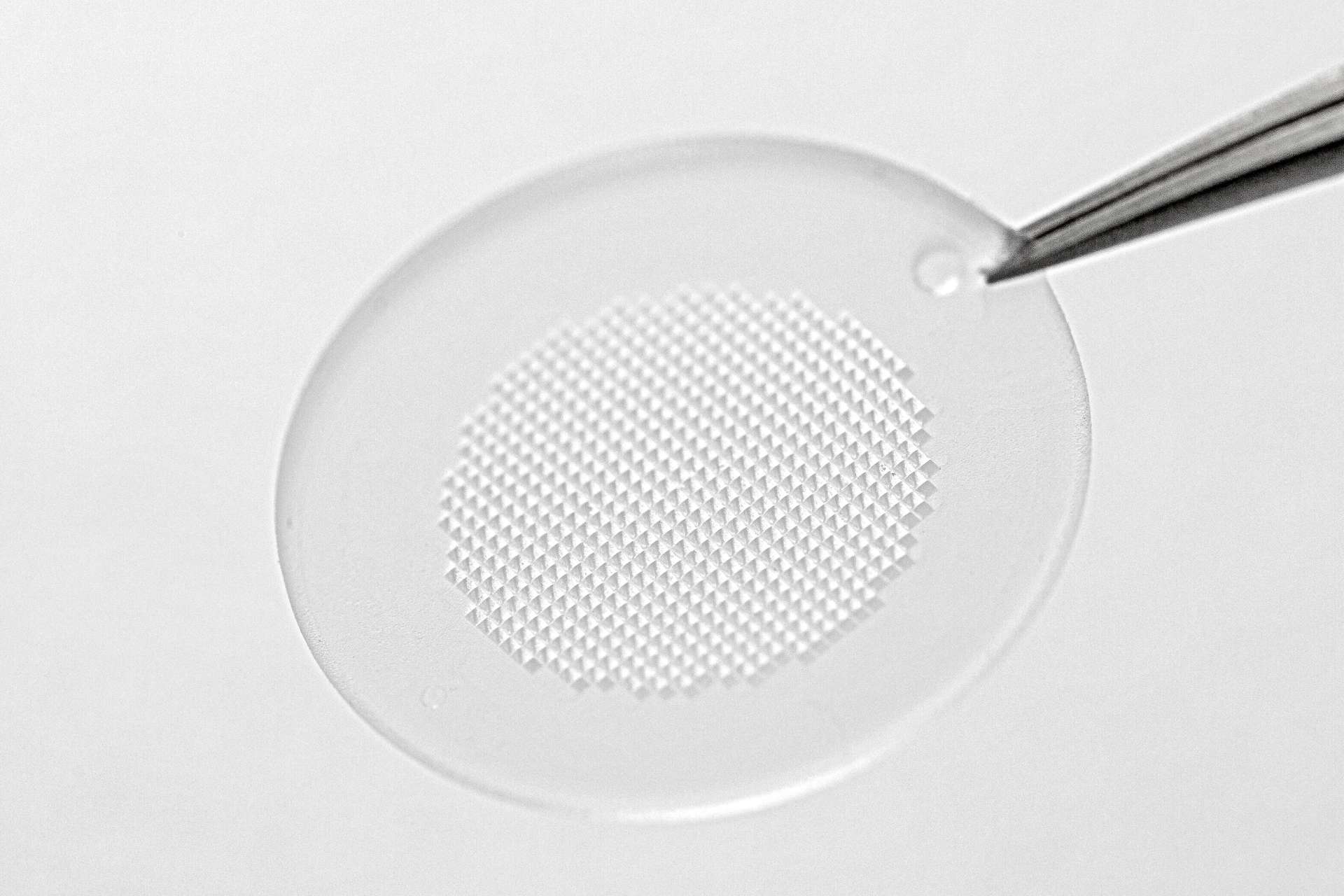

We CARE. We CREATE. We DELIVER. The driving philosophy behind LTS. As a trusted technology partner for the pharmaceutical industry, we develop and manufacture innovative drug delivery systems such as Transdermal Patches (“TTS”) and Oral Thin Films (“OTF”) as well as wearable drug delivery devices (“OBDS”). LTS´ commercial offering encompasses more than 20 marketed products and a diverse pipeline of more than 40 development projects targeting multiple disease indications. LTS’s innovation pipeline contains both partner-funded as well as proprietary, LTS-funded projects. LTS maintains its leading position through the continuous refinement of its core TTS and OTF technologies and by advancing emerging drug delivery technologies, including Microneedle Array Patches (“MAP”) for the transdermal delivery of small and large molecules, biological actives and vaccines. With its SorrelTM wearable drug delivery platform LTS offers patient friendly solutions for complex drugs delivery at home. Founded in 1984, LTS operates today from four sites: in Andernach, Germany, West Caldwell, NJ, USA, St. Paul, MN, USA and Netanya, Israel. LTS has also a representative office in Shanghai, China.

About Grand River Aseptic Manufacturing, Inc.

Grand River Aseptic Manufacturing, Inc., a prominent aseptic fill-finish contract development and manufacturing organization, delivers biologics, small molecules, and vaccine capabilities for liquid and lyophilized vials, syringes, and cartridges. Grand River Aseptic Manufacturing’s 450,000 sq. ft. of sophisticated GMP space supports customers’ drug products with advanced equipment, innovative technology, and a breadth of experienced team members.

Contact

Dr Iris Schnitzler